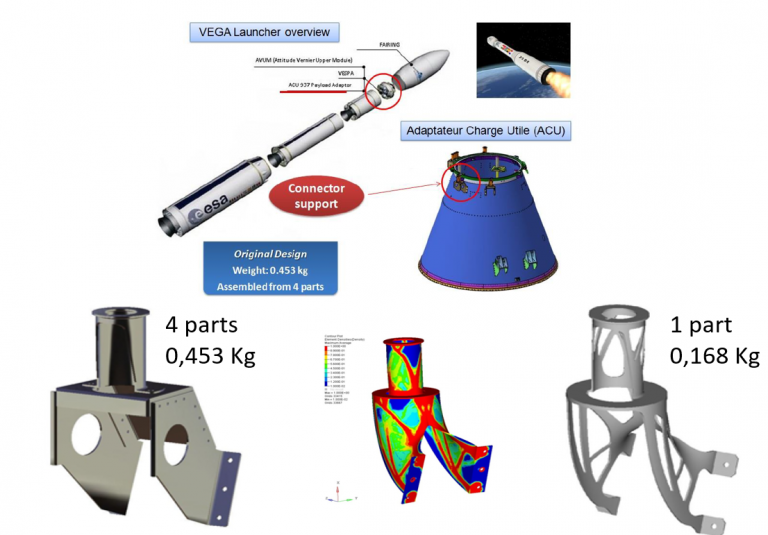

The main advantage of additive metallic manufacturing in the aeronautic and aerospace sectors is, first, weight reduction, making aircraft safer, lightweight, efficient and capable of carrying heavier payloads.

The reduction of the number of components obtained with this technology is also a factor of great interest, reducing the complexity and defects typically associated to the joints in more demanding environments, with heavy vibrations and thermal amplitudes.

Other applications in these sectors:

– Turbine blades

– Complex titanium parts that are difficult to mill

– Combustion process components with cooling channels

– Heat exchangers

– Optimized structural supports

– Instrumentation boxes

– Fuselage of UAVs

– Spare parts

– Prototypes without tooling cost

– Jigs and templates

Most used materials in Aerospace and Aeronautics:

– Titanium

– Aluminum

– Cobalt Chromium

– Inconel

– Stainless steel

At Hypermetal we also offer heat treatment solutions for dimensional stabilization and hardening.