Engineering

Focused on product quality and customer service, this is our range of engineering services.

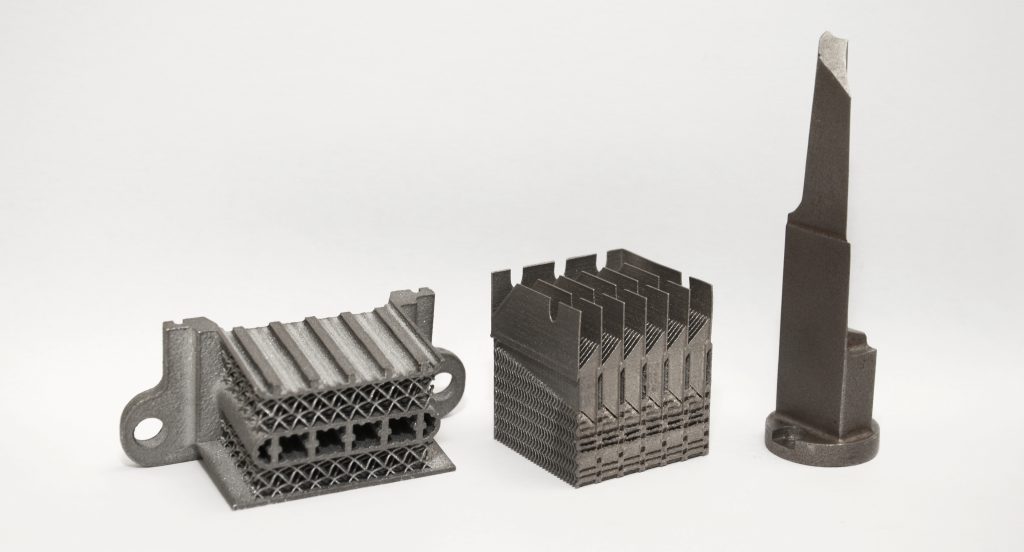

Conformed Cooling Channel

We design the cooling channels for mould inserts. The use of these inserts increases the efficiency of the production in the injection phase, improves the quality of the final parts and reduces cycle times.

Production Engineering

In cases of incorrect, incomplete or non-existent documentation, we have the ability to recreate components, analyzing the parts geometry and functionality in detail, and using scanning, measurement and 3D modeling technologies.

Topology Optimization

Structural analysis using the finite element method. This method considers the properties of the materials, supports and applied forces, in order to optimize the geometry for weight reduction.

All material that is not essential is simply removed, ensuring the same strength of the part to the boundary conditions.

This approach typically results in organic forms, extremely difficult (if not impossible) to obtain by traditional technologies, but easily achieved by additive manufacturing.

DfAM - Design for Additive Manufacturing

When the production of final parts by additive manufacturing is an option, it’s important to intervene since the beginning of product development in order to take full advantage of this technology.

At Hypermetal, we support the Client’s engineering team by adapting the project and meeting the requirements.

Feasibility Analysis and Implementation

We support the Client throughout all phases of the feasibility analysis and subsequent implementation: we study potential applications where this technology will bring advantages, analyse the Client’s parts database and identify improvement opportunities with a positive economic impact.

Project Optimization for Production

In cases where there is freedom to adapt the geometry, it’s advantageous to adjust certain features, such as angles and orientations, in order to optimise the production. This way it’s possible to minimize the need for support structures and post-processing, resulting in a cost reduction.

DETAIL AND ACCURACY

To take full advantage of our technology potential, a transversal approach to each application is essential, intervening whenever possible from the conceptual phase of product development or in an adaptation perspective of the existing one to the additive manufacturing.

Contact us today to learn more.