INDUSTRIAL / TOOLING / MOULDS

For industrial applications, this technology is used to obtain complex parts – the greater the complexity, the greater the advantages of the additive option – as well as single parts or small series with very short lead times.

Obtaining functional prototypes without tool costs is also of great importance, it allows the simultaneous manufacture of several parts with different thicknesses or variations of any other parameter that one wishes to iterate and optimize for validation tests.

For tooling applications, this technology allows the production of tools with complex geometries, with internal channels for the passage of coolant, which allows precise projection in the cutting area, even in difficult access situations.

The plastics mould industry particularly benefits from the additive manufacture in the case of inserts with conformed cooling channels.

The use of these inserts reduces the injection cycle and achieves significant productivity gains. These channels can be designed to match the contour of the insert very close to the surface, maximizing cooling performance and increasing mould life.

Other applications: spare parts, jigs, and templates

Most used materials in these sectors:

– Tool steel

– Stainless steel

– Aluminium

At Hypermetal we also offer heat treatment solutions for dimensional stabilization and hardening.

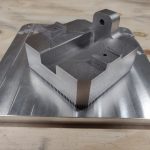

Hybrid Inserts for Moulds

When a mould insert has a base with a simple geometry and straight cooling channels plus a complex top portion, it can be obtained by hybrid production: CNC machining + Metal AM

The complexity of the interior channels in the top makes it impossible to be produced by traditional technologies.

This way the additive portion of the part is done only where it really adds the value, resulting in an economical solution.

In Hypermetal we have the engineering capacity and all the equipment to provide the complete service, from the design of the channels, machining the bases, printing the top and finally hardening the parts by heat treatment.