Inconel 718 Components for Aerospace Propulsion: A Precision Journey

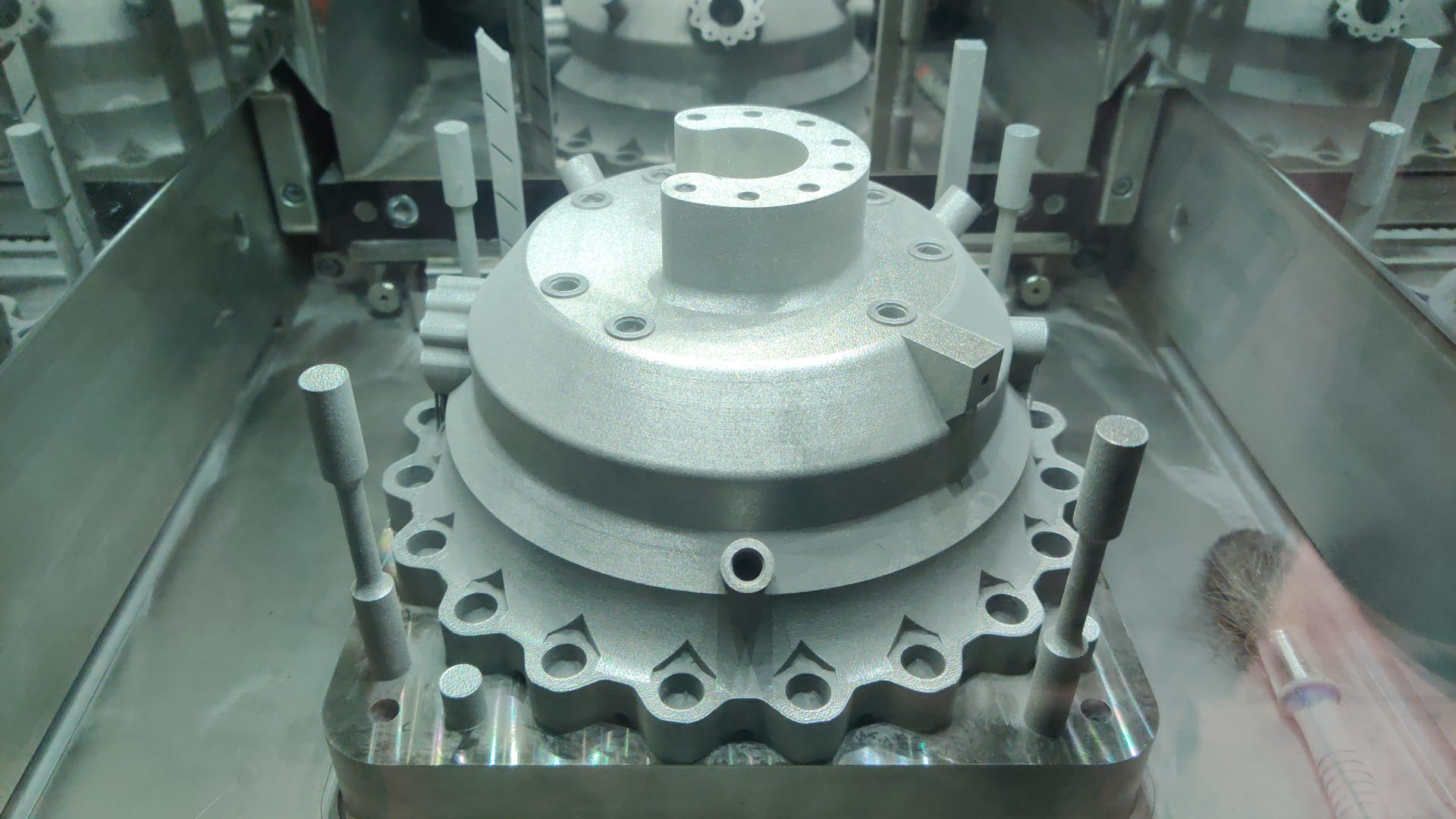

In this photo we show you our furnace, equipped with thermocouples and data acquisition system. This setup is crucial for ensuring the highest quality in the production of parts through metal additive manufacturing.

We are currently processing Inconel 718 components for a propulsion system in the aerospace sector, directly from the printer to the furnace. These critical parts demand mechanical prowess and structural integrity, and our furnace delivers precisely that.

Temperature Curves: Our Obsession with Perfection

At Hypermetal, precision isn’t a buzzword; it’s our DNA. We meticulously record and monitor temperature curves throughout the entire manufacturing process. Why? Because excellence demands nothing less. Our metallurgical engineer, Filipe Silva, oversees every operation, ensuring each piece meets—and exceeds—our rigorous quality standards.