Metal additive manufacturing can also be a feasible option for bulkier parts. In this case, a customized Jig is required for an assembly process.

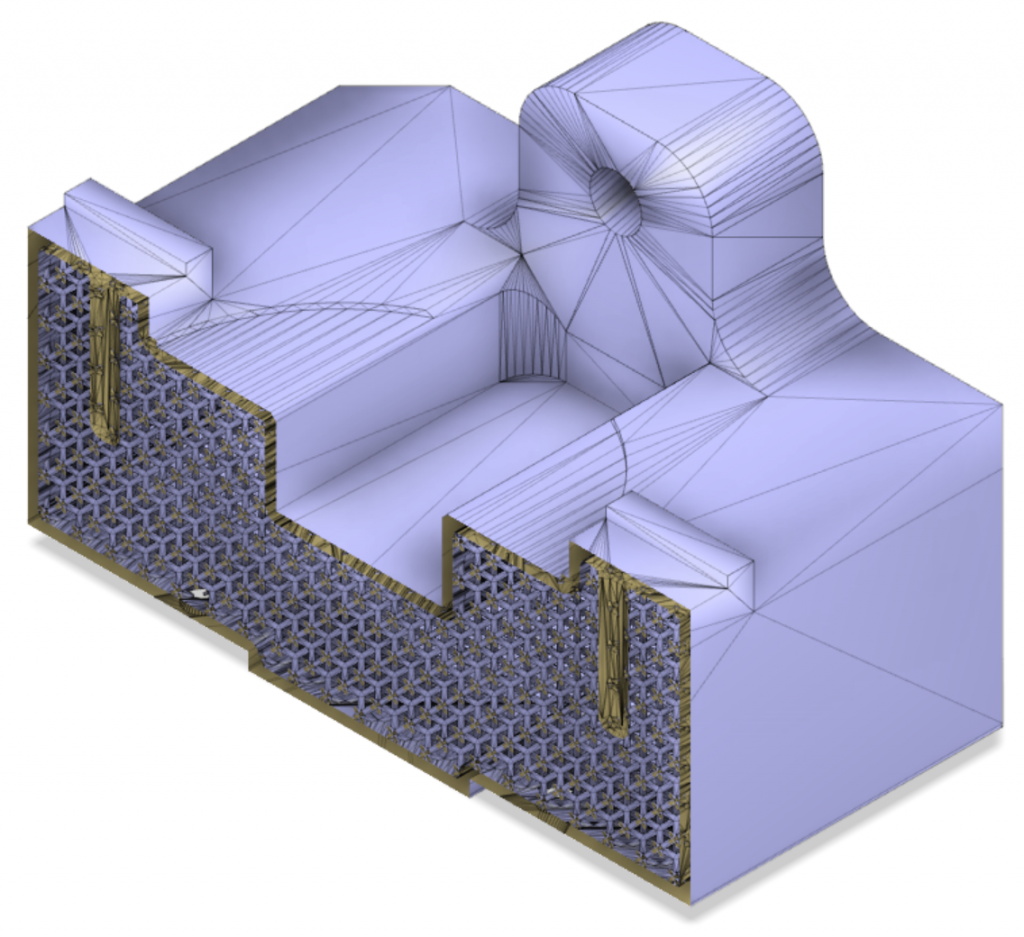

Replacing the solid interior by a lattice structure we can maintain the required external geometry and rigidity while reducing the material quantity. This optimization would be impossible to manufacture by traditional manufacturing technologies.

Continue reading for more information on the process steps:

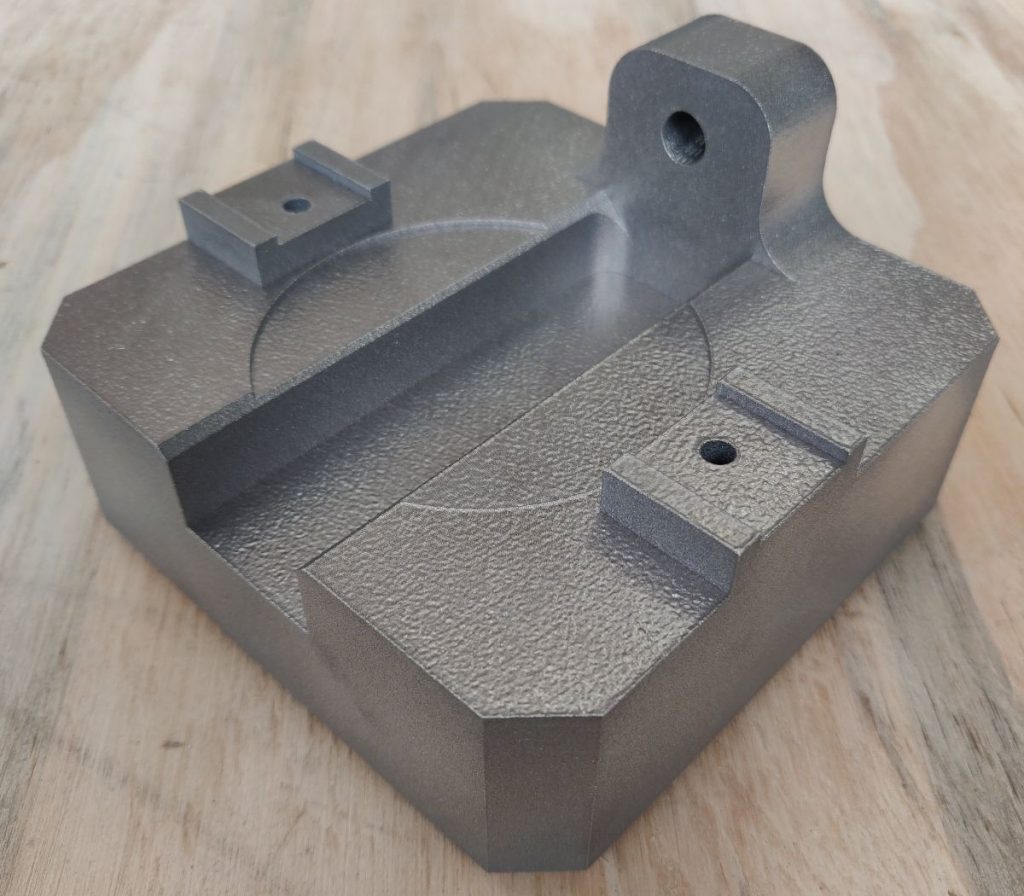

The initial design

A customized Jig that was developed to be manufactured by CNC milling. This part weights 1,5Kg and producing it as it is by Metal AM would be very time consuming due to the solid interior, which doesn’t add any value to the final purpose of the part.

Optimising the part

Simply by replacing the solid interior by a lattice structure, designed to guarantee the original external geometry and required rigidity, we can reduce the weight by 70%, meaning much fewer production hours resulting in a feasible manufacturing solution cost-wise. The increased complexity makes absolutely no difference in this technology.

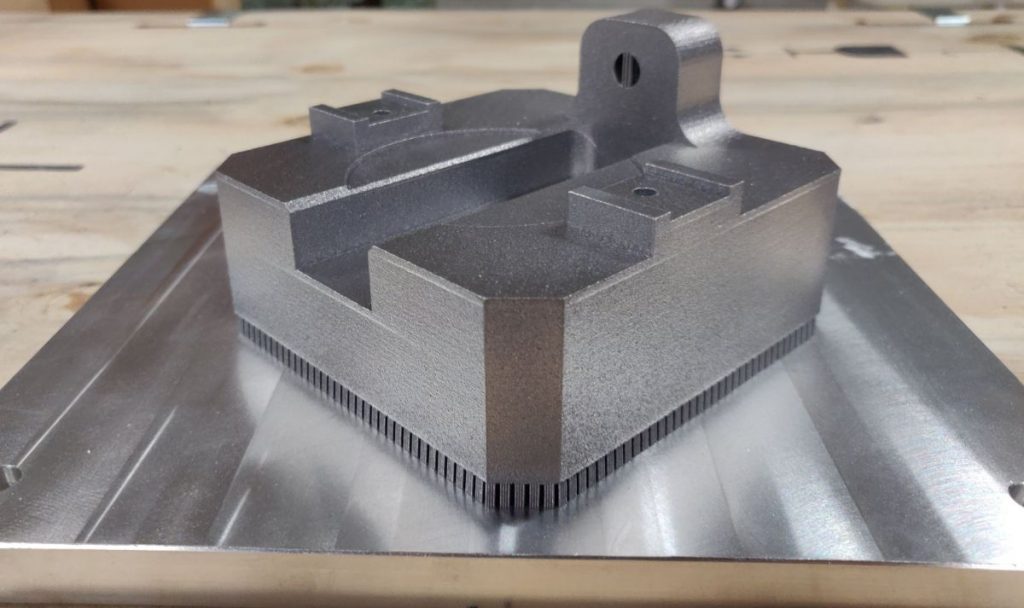

The build process

This complex shape is produced layer by layer and all powder that is not processed in the process is reusable, resulting in minimal waste.

Post-processing

Separation of the part from the base plate by removing the supports under the part and in the horizontal hole. All supports were designed to be manually removed.

The final part

After separation, a glass bead blasting treatment was done for cleaning and surface treatment.

This part was ready for expedition in just 2 working days.

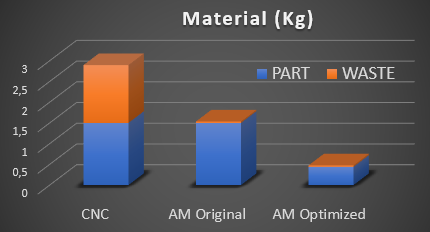

Material Savings

Comparison of the material needed to obtain the same part and respective waste when using:

– CNC milling from a solid block;

– Additive Manufacturing without optimization;

– Additive Manufacturing with optimization.